ATV Brake Basics: Part II

Dec 19th 2018

ATV Brake Basics: Part II

On our last episode of Brake Basics, we went over the fundamentals of off-road powersports brakes, their purpose, and essential care and feeding tips for the purpose of getting the most performance and longevity out of your ATV or UTV’s brake system.

In this segment, we’re going to go in-depth about the specific parts of an ATV’s disc brake system--the calipers, the brake pads, and the brake rotors--and which types you should consider when fortifying the stock OEM setup.

WHY DISC BRAKES?

Before the days of motor vehicles--when horsepower really meant horse power, as in horse-drawn carriages and buggies--the earliest braking mechanisms were lever-actuated manual brakes akin to those found on a bicycle. Unsurprisingly, these were born of the same concept as railway brakes for trains. Since bicycles, push carts, and horse and buggies did not regularly travel at speeds in excess of 20 MPH, these primitive brake designs were effective enough in their purpose. The first motorcycles, which were introduced around the same time as the first motorcars during the late 19th century, also used brakes that were derived from bicycles. The first major step in modern vehicle brakes came in 1902 when French entrepreneur Louis Renault (founder of the Renault automobile brand) introduced the mechanical drum brake; an improved redesign based off of Wilhelm Maybach’s hand-operated drum brakes that were used in the first Mercedes car.

Drum brakes soon became the standard for cars but in the following years, as technology advanced and ground speeds increased, car performance exceeded the capabilities of drum brakes. After World War II, disc brakes came into prominence after having proved their effectiveness and efficiency in stopping fighter planes and German Tiger tanks. Jaguar’s winning entry in the 1953 24 Hours of Le Mans race featured disc brakes and in 1955, the Citroën DS became the first production passenger car to use disc brakes.

Disc brakes offer superior braking performance through thermal management. Because disc brakes are exposed to the open air, they bite harder and cool faster than enclosed drum brakes. Disc brakes are also more resilient in wet environments as water can sling off of the rotor surface almost immediately. Disc brakes are also self-adjusting and are far less complicated to maintain and service than a drum brake and its multitude of springs, clips, and components.

Most passenger cars and trucks use disc brakes in the front and rears but there are still some that use drums in the rear but in high-performance street and track vehicles, you won’t find anything other than disc brakes behind the wheels. The same goes for motorcycles, ATVs, and UTVs. High-performance off-road racing ATVs tend to use discs on all four wheels to compliment the enhanced power output and handling capabilities. Because, after all, power is nothing without control.

#1: BRAKE CALIPERS

The brake caliper is what distributes the clamping force onto the friction surface. There are two major types of brake calipers: floating (sliding) and fixed (solid).

Floating calipers are the most common type of brake caliper on cars, trucks, touring motorcycles, ATVs, and UTVs. The caliper bracket is fixed to the steering knuckle while the caliper itself is held in by pins. This allows the caliper to slide in and out. A piston (or pistons) on the inner side of the caliper pushes the brake pad onto the rotor, as if to push the rotor itself. Since the rotor cannot slide, the outer side of the caliper takes the pushing force and slides outward. The outer pads also press against the rotor face in order to slow or stop the vehicle. Floating calipers are cheaper to produce, tend to be lighter, and allow for compact packaging but these reasons are also why it is so much easier to overwhelm a set of floating calipers in a high-speed, high-braking situation.

Fixed calipers (solid, or monoblock/MONOBLOC) are attached to the steering knuckle, like a floating caliper, but uses pistons on both the inner and outer sides of the caliper to push the pad down onto the brake rotor. Fixed calipers use solid housing and can employ the use of 2, 4, 6, and even 10 pistons (pots) in their design. Most ultra high-performance and race applications use fixed calipers and they often come equipped on many high-horsepower, high-speed performance cars, trucks, and powersports vehicles for the street and track. The advantages of fixed calipers include strengthened housing (versus floating caliper type), even distribution of piston pressure, and elevated thermal management capabilities. On the other hand, fixed calipers are costlier to produce and service, they are notably more mechanically-complex in design and operation, and they are also larger and heavier than the ordinary sliding caliper. Keep in mind that while there will be an increase in unsprung mass with a large fixed caliper brake setup, it is also far more robust and can endure a greater amount of use and abuse.

All brake calipers have common core parts that need to be observed and maintained over time. Rubber dust boots and piston seals can crack and deteriorate. Pins and pistons can seize and lock up, rendering useless their ability to clamp down onto a rotor. Be sure to periodically inspect the physical and mechanical condition of your brake calipers. If you are in need of a full replacement brake caliper for your ATV, we have OEM brake calipers for sale that include all the necessary bolts, washers, and mounting brackets.

#2: BRAKE PADS

The pistons inside the brake caliper apply pushing force onto the brake pads. The brake pads, in turn, make contact with the brake rotor and create friction.Not all brake pads are created equal--and that’s done intentionally. Not all of us ride the same machine and not all of us share the same riding style. That’s why there are a multitude of different brake pads; each one created to best suit the type of environment in which they will be subjected. The three main pad compound types were already covered in our earlier post but in case you need a refresher, they are as follows:

- ORGANIC

- METALLIC

- CERAMIC

ORGANIC brake pads were developed as replacements to the original asbestos-type brake pad when it was discovered that asbestos was a carcinogenic. Organic pads are the most common, run-of-the-mill type of brake pad that’s designed to handle regular, non-performance riding.

METALLIC pads improve upon the organic compound with higher amounts of metallic abrasive materials for greater friction. These are available as SEMI-METALLIC or FULL-METALLIC with the higher amount of metal content intended for more severe braking use.

CERAMIC brakes blend the best of both organic and metallic with riding versatility, ease of use, and increased durability but these should be considered as street-only upgrades; not suitable for any kind of performance, competition, or racetrack environment.

There is a fourth type of brake system that was recently introduced into the consumer motorsport enthusiast market, CARBON CERAMIC. This is actually a combination of a specialized parts that use a baked ceramic and carbon fiber rotor a specialized pad (neither full organic, full metallic, or full ceramic) that is purposely-built to only be used on carbon ceramic rotors. These are the ultimate in extreme braking performance and come stock on a number of supercars including the McLaren 570, Ferrari 458, Porsche 911 GT3, Aston Martin DBS Superleggera, and the Chevrolet Corvette ZR1. In the motorcycle aftermarket, suppliers are developing MotoGP-inspired carbon ceramic brakes for super sport bikes like the Yamaha R1 and Triumph Daytona 675. Hyper-performance cars and motorcycles benefit from carbon ceramic brakes due to their extreme heat tolerances and super-lightweight construction, both of which make them virtually impervious to brake fade; the gradual-to-sudden loss of braking power under load or high speed.

Speaking of brake fade, it is one of the factors that determine the official Department of Transport (DOT) classification for brake pads. The DOT mandates that all street legal brake pads fall under a specific grading system between the letters E through H; E being the minimum requirement and H being the maximum. This two-letter edge code can be found printed on the brake pads and are used to identify the pad’s fade resistance.

| Official DOT Edge Code |

Coefficient of Friction (CF) @ 250°F and @ 600°F |

Comments |

| EE | 0.25 to 0.35 (both temperatures) | 0 to 25% fade possible at 600°F |

| FE | 0.25 to 0.35 @ 250°F | 2 to 44% fade possible at 600°F |

| 0.35 to 0.45 @ 600°F | ||

| FF | 0.35 to 0.45 (both temperatures) | 0% to 22% fade possible at 600°F |

| GG | 0.45 to 0.55 | VERY RARE |

| HH | 0.55 to 0.65 | Carbon/Carbon only. |

| OK up to 3000°F where it glows. |

The coefficient of friction (CF) is rated between 250°F (cold) and 600°F (hot). The first letter of the two-letter code represents the CF grading at 250°F and the second letter at 600°F. Each letter grade can have a significant range in CF, but a difference in letter grade can denote brake fade. While the letters can be in any order, they do not mean the same thing. For example, FE pads fade when hot but EF-grade pads won’t grab when cold. Brake pads that are rated FF are considered to be entry level within the high-performance category. Most high-performance street pads are rated FF at a minimum.

#3: BRAKE ROTORS

The ‘disc’ in disc brakes, brake rotors are where the friction materials (the brake pad) mate in order to produce friction for stopping power.

Unlike an automotive brake rotor found on a car or truck which can be internally vented (venting channels that are sandwiched between two solid slabs of rotor material which is cast into place), motorcycle and ATV/UTV brake rotors are typically solid pieces of steel or iron. Powersports brake rotors are also much thinner than car or truck rotors, mainly because vehicles like motorcycles and ATVs only weigh a fraction of what the average passenger car weighs. Far less force is required to stop a motorcycle, ATV, or UTV versus a car that can weigh up to and over 2 tons.

However, like automotive brake rotors, brake rotors for powersports machines can be made as single-piece or two-piece designs. A single-piece brake rotor is cheaper to manufacture and is generally suitable for most regular, non-performance applications. Two-piece rotors separate the rotor face (surface) from the mounting point (hat) in an effort to reduce unsprung mass. While these types of rotors are more expensive to produce, they can be cheaper for the consumer to replace as only the rotor face can be discarded and swapped with a new piece while retaining the mounting point.

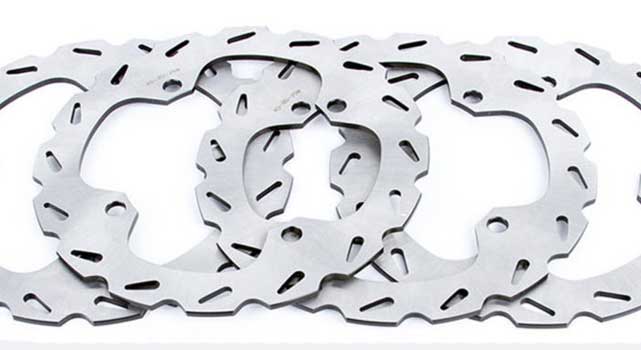

As for the rotor face itself, they can be completely solid (blank), drilled, slotted, or wave cut. Solid rotor faces provide even wear and grip and make up the majority of standard rotors. Drilled rotors feature small holes placed throughout the surface in a specific pattern. The reason for this is heat dissipation and weight reduction but with the loss of valuable real estate for friction, this makes warping, cracking, and heat damage much easier to occur. Slotted rotors take the drilled concept further and instead of holes, larger and wider grooves are cut into the rotor surface. Unlike a slotted brake rotor for a car, the slots on a motorcycle or ATV rotor cut straight through the surface as it would be on a drilled rotor. Wave cut rotors transform the round, circular shape of the brake rotor and through cutting and carving, create a serrated blade-like design. Wave cut rotors allow for maximum heat dissipation and cooling, the most effective way of weight reduction in the brakes, but all at the cost of structural integrity. The potential for heat stress damage is increased with wave cut rotors, but is not guaranteed. Plus, some riders appreciate the aesthetic quality of exotic-looking wave cut brake rotors as opposed to traditional round rotors.

Race Driven has engineered three separate kinds of ATV brake rotors: Standard, MudRat, and RipTide.

The Race Driven STANDARD rotor is the basic OEM-spec replacement rotor. These are available in either drilled or solid face (depending on your vehicle’s original stock rotor) and offer performance that either meets or exceeds the stock performance of your motorcycle, ATV, or UTV brakes. Standard rotors are recommended for normal riding situations, not intended for competition or extreme use.

The Race Driven MUDRAT rotor is a solid face rotor designed to withstand the abusive conditions of mudding and off-road travel. Mud is full of debris and contaminants that can heavily score the surface of a brake rotor, which is why MudRat rotors do not feature drilled holes, slots, or grooves that can trap and collect abrasive dirt and mud. Keep in mind that mud is bad for ALL kinds of brakes. Just because the MudRat rotor can endure more abuse, they are not invulnerable to the damage caused by mudding. MudRat rotors are recommended for light mudding, shallow creek and low water traversing, but not for competition or extreme mudding.

Lastly, the Race Driven RIPTIDE rotor is for high-performance riding. Inspired by the racetrack, RipTide rotors feature a wave cut design with extra cooling slots. These brake rotors work best when combined with Race Driven sintered metal brake pads for a cost-effective upgrade to the stock system that matches or outperforms the leading aftermarket brands. Race Driven RipTide brake rotors are made from tempered stainless steel for not only a great look but also optimal performance. Also, the extra venting that is cast into the rotor surface helps to cool down your brakes in dry and heated riding conditions. For high-performance motorcycles, ATVs, and/or UTVs that experience high speeds and plenty of hard braking and cornering, the RipTide rotor is best for the street and on the track. Not recommended for mudding or in wet, moisture-rich conditions.

As one of the leading manufacturers of high-performance brakes in the aftermarket powersports industry, we hope we’ve made understanding your motorcycle, ATV, or UTV’s brakes a little easier to digest. Race Driven brake pads and brake rotors are value-oriented, top-quality performance parts that rival products from the biggest and most famous brand names, thanks to lessons learned throughout our collective lifetime of on-track racing experience.